System27

†

Marzo

†

2014

System27

†

Marzo

†

2014

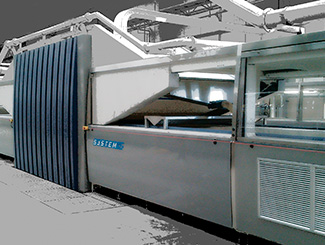

GEA Technology spreads to the Far East

There are certain process inventions destined to improve the world of ceramics forever. This is the case with the press without a mold, GEA, the System technology - already in use in Europe at Panaria Group (Italy), Levantina (Italy), The Size (Spain) and in Turkey, in the factories of KŁtahya and Kale - now spreading to the Far East.

In the first months of the year, System signed agreements with leading companies such as SCG Group in Thailand and Platinum in Indonesia to supply complete lines - i.e. from kiln loading systems to "end of line" - and in the meantime signed an agreement in the ceramic sector with

another local

primary

company for GEA, the press without a mold.

The market today requires large ceramic tiles. System has had the solution for a decade: on February 24, 2014, the first ceramic tile produced with System Lamina technology at the Laminam (a System subsidiary) factory, turned 10 years old. An efficient process which is continuously improving and currently allows companies to enjoy 50% savings in energy consumption compared to conventional molding.† With this automation, companies can produce ceramic surfaces of variable thicknesses in large or small lots, according to market requirements. The System Lamina process enables the production of structured surface patterns up to a maximum of 1.8 mm and perfect flatness is ensured by the management system of the atomised raw material. On all thicknesses, even the higher ones, deaeration is slow and the fact that the press is designed to be free on all edges allows air to be obstacle-free during unloading i.e. during pressing.

The

worldwide group

of ceramic tiles, SCG Group, has signed an important agreement with System for the supply of a new line that is completely customised and dedicated to the production of large tiles of variable thicknesses. Special supply was arranged for the press without a mold, GEA 32000, that will allow SCG Group to produce innovative roofing materials with variable thicknesses ranging from 3 to 20 millimetres. The maximum dimensions of the pressing area will be 1.4 by 3.6 metres. System has also designed and built the entire system, automated with Nuova Era technology for storage, kiln loading and unloading, unit and shelf handling with dedicated laser-guided vehicles and the packaging line with Multigecko and 4Phases.

In the ceramic district of Sassuolo (Modena, Italy), System has signed an agreement with a well-known local company that has chosen the press GEA for the establishment where it produces surfaces up to 3.2 by 1.6 metres in size with only 60 kW/h of power consumption. Compared to a traditional press, the factory will see 50% in energy savings. The perfect flatness of the finished product, the absence of material tension, the option of creating tiles with thicknesses ranging from 3 to 20 millimetres and the flexibility of creating structured surfaces were the most appreciated features.