by B. Mazzanti*, E. Rambaldi*, K. Harlow**, M.C. Bignozzi*28

Agosto

2019

by B. Mazzanti*, E. Rambaldi*, K. Harlow**, M.C. Bignozzi*28

Agosto

2019

Cool materials and buildings energy needs

The present study by Centro Ceramico (Bologna, Italy) was carried out to evaluate the effect of zircon addition to ceramic glazes of various colours.

One of the solutions to mitigate the urban heat island effect consists in the use of external flooring materials and components for the building envelope, with high radiative properties, so-called cool materials.

It has been widely demonstrated that materials with high solar reflectance and high thermal emissivity used as roofing are able to reduce the buildings energy needs for summer cooling, and the consequent emissions of CO2 into the atmosphere.

The achievement of a better hygrometric comfort is demonstrated by literature data, which show a decrease of the indoor temperatures of about 2.5 ° C

(1)

.

With regard to the consequent reduction of energy required for cooling, variable data according to the climatic zone are reported: for example it was estimated a reduction of 43% in Florida and 30% in Rome

(2)

. Among the best known high reflectance materials used for cool roof construction, there are spray paints and sheaths, waterproof membranes, polymer bitumens, but also corrugated sheets and ceramic tiles; in particular, the paints are white, with high solar reflectance (ρ

s

> 0.8) and excellent thermal emissivity (ε = 0.9).

Nevertheless, in recent years, in addition to assessing the initial performance of the products, more and more attention has been focused on the long-term performance maintenance of cool materials. Although the data on the optical-radiative degradation along the useful life of these materials are still scarce, tests in outdoor environment have shown that roofs made of bituminous membrane coated with cool acrylic paint, due to exposure to atmospheric agents and fouling, undergo a degradation of the solar reflectance characteristics almost to halving their value (from ρ

s

= 0.8 to ρ

s

= 0.46) within two years

(3)

. In a future scenario of urban centres consisting of zero-energy buildings, energy performance must be guaranteed over time, as well as the characteristics of the materials that make it possible to achieve them. To date, due to the deposition of dirt and degradation, cool coatings require periodic washing, maintenance or restoration treatments; to reduce the number of these interventions, in some contexts it could be advantageous to use materials with high durability physical-chemical characteristics, such as ceramic tiles.

At present the results of various tests that are conducted for the quality certification of these products - such as the freeze-thaw cycles (ISO 10545-10), thermal shock (ISO 10545-9) and solidity of the colours to light (DIN 51094) - highlight how porcelain stoneware tiles do not undergo colorimetric variations or solar reflectance due to UV radiation or hygrothermal shocks. The choice of adding a component such as zircon in ceramic glazes, that is able to increase solar reflectance, can be a way to improve the potential of ceramic tiles as a cool material. An added value compared to the already existing cool materials on the market is represented by the fact that ceramic glazes in general, and those containing zircon in particular, are characterized by greater durability in terms of resistance to chemical attacks and wear. Furthermore, with a view to reduce building maintenance costs, ceramic glazes can be designed with a surface finish to increase the tiles cleaning performance.

The present study was carried out to evaluate the effect of zircon addition to ceramic glazes of various colours. The production of glazes was carried out at laboratory scale by using a base of industrial glaze. Table I shows the denominations of the studied enamel samples: the zircon was added to the glazes both as opacifier, and then inserted directly into the glaze formulation (up to 10 wt%), and as frit component (up to 6.6 wt%).

Table I - Name of the glazes on the basis of their colour and zircon content.

|

Base glaze + Pigment |

Zircon as opacifier (Op) | ||

|

0 wt% |

5 wt% (Medium) |

10 wt% (High) | |

|

Uncoloured |

Uncoloured _Op |

Uncoloured _5_Op |

Uncoloured _10_Op |

|

Yellow, 3 wt% |

Yellow_Op |

Yellow_5_Op |

Yellow_10_Op |

|

Green, 3 wt% |

Green_Op |

Green_5_Op |

Green_10_Op |

|

Brown, 3 wt% |

Brown_Op |

Brown_5_Op |

Brown_10_Op |

|

Blue,3 wt% |

Blue_Op |

Blue__5_Op |

Blue_10_Op |

|

Black, 3 wt% |

Black_Op |

Black_5_Op |

Black_10_Op |

|

Base glaze + Pigment |

Zircon as frit component (F) | ||

|

0 wt% |

3,3 wt% |

6,6 wt% | |

|

Uncoloured |

Uncoloured _F |

Uncoloured _3,3_F |

Uncoloured _6,6_F |

|

Yellow, 3 wt% |

Yellow_F |

Yellow_3,3_F |

Yellow_6,6_F |

|

Green, 3 wt% |

Greene_F |

Green_3,3_F |

Green_6,6_F |

|

Brown, 3 wt% |

Brown_F |

Brown_3,3_F |

Brown_6,6_F |

|

Blue,3 wt% |

Blue_F |

Blue_3,3_F |

Blue_6,6_F |

|

Black, 3 wt% |

Black,_F |

Black,_3,3_F |

Black,_6,6_F |

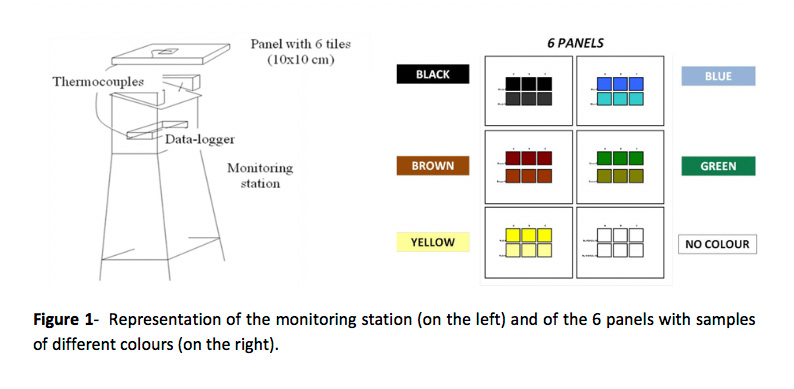

The solar reflectance index (SRI) was calculated on all 36 glaze samples and the CIELab L *, a *, b * colorimetric coordinates were also determined, to evaluate any colour variation due to the presence of zircon. The thermal performances of the samples were then studied once they were exposed in outdoor environment during the summer period (from June to September). The exposure took place by mounting the samples on a panel in horizontal position (inclination angle 0°) to simulate the behaviour of a pavement. Both the environmental conditions in terms of temperature and relative humidity and the temperature variations on the surface of the samples were monitored by using an automatic recording system set up to record data every 30 minutes. The monitoring station and the structure of the panels on which the samples were fixed are shown in Fig. 1: this design made it possible to monitor the group of samples of the same colour under the same environmental conditions.

Figure 1- Representation of the monitoring station (on the left) and of the 6 panels with samples of different colours (on the right).

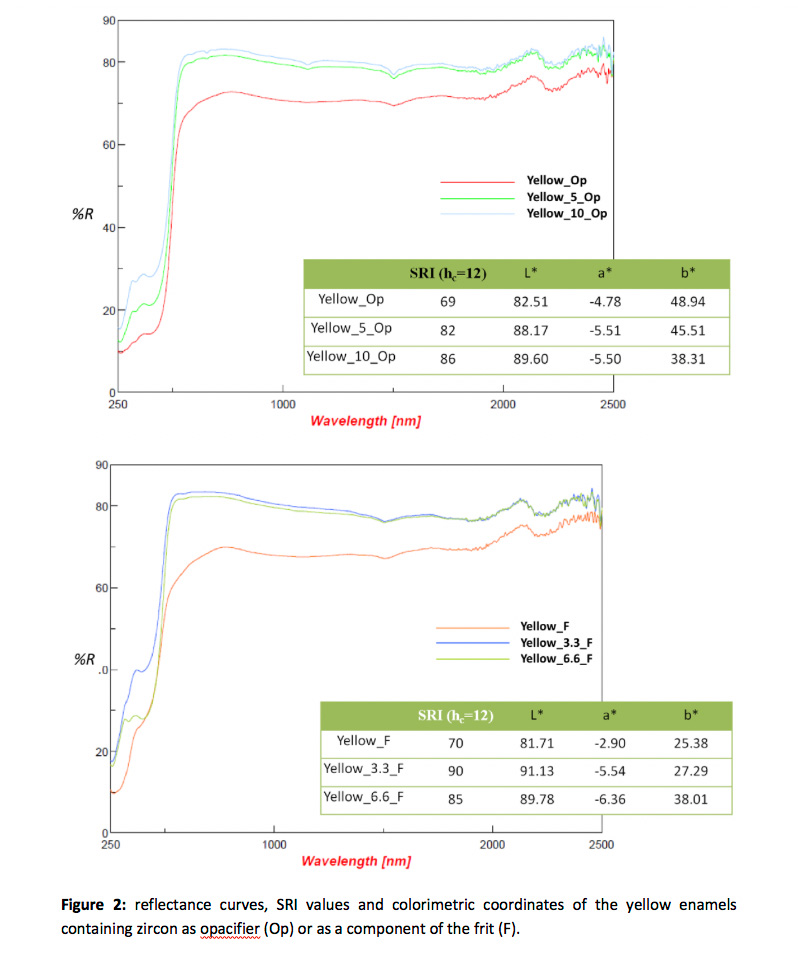

The measured solar reflection spectra show that generally the addition of zircon produces a curve rise in the wavelength range of the visible spectrum (390-780 nm) and in the near-infrared spectrum range (NIR, 780-2500 nm); in some cases also in the UV range (250-390 nm). This effect is more pronounced when zircon is added as opacifier.

Fig. 2 shows an example of the reflection spectra, the SRI values and the colorimetric coordinates of the yellow glaze samples. The value of SRIs for glazes with a greater quantity of zircon is related to the increase in colour brightness (parameter L * of the colorimetric coordinates) together with that of the spectral component of the NIR interval. It is known that zircon, in ceramic formulations, has a bleaching effect and, in this study, it is highlighted by the linear increase in the L * colorimetric coordinate, linked to the colour brightness. The sunlight is undoubtedly influenced by the bleaching of the glaze colour, but it is not proportional to the content of the zircon, as results demonstrate. For all the colours, the different frit composition entails that glaze with 3.3 % of zircon in the frit has a higher value of L * and a higher value of SRI than the one with 6.6%.

Figure 2: reflectance curves, SRI values and colorimetric coordinates of the yellow enamels containing zircon as opacifier (Op) or as a component of the frit (F).

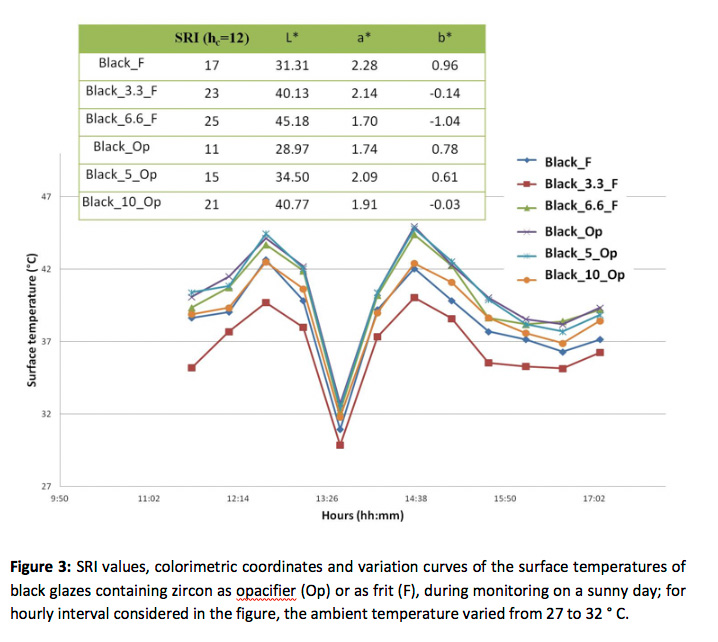

The surface temperature curves of the samples obtained by processing the external monitoring data reveal that, comparing the same colours with different contents of zircon, the lighter glazes (with higher values of L * and SRI ) remain colder.

Fig. 3 shows the curves of monitoring of the surface temperature of black glaze samples. The graph shows that the black sample with 3.3% of zircon in the frit, exposed to solar radiation, maintains lower surface temperatures, up to 5 ° C, compared to the other black glaze samples.

Figure 3: SRI values, colorimetric coordinates and variation curves of the surface temperatures of black glazes containing zircon as opacifier (Op) or as frit (F), during monitoring on a sunny day; for hourly interval considered in the figure, the ambient temperature varied from 27 to 32 ° C.

The tests carried out on the samples of glazed ceramic tiles showed that, in general, the addition of zircon increases the solar reflectance property of the glazes.

This effect is more evident when the zircon is added as opacifier and, as its percentage in the glaze increases, the SRI value increases linearly for all the colours analysed. The monitoring in outdoor environment of the temperatures of the ceramic surfaces exposed to solar radiation confirms what it is expressed by the higher reached value of the parameters of brightness and solar reflectance of the glaze with the addition of zircon.

Excluding the colour appearance, the improvement in terms of decrease in surface temperature is observed in the glazed samples with higher spectral curves in the NIR range, in particular after 1500 nm. The increase in spectral values in this range is an effect that can be related to the addition of zircon in glazes.

In conclusion the study shows that zircon can increase the cool effect in the composition of glazes for ceramic tiles. These tiles, if used as a building envelope, are able to improve the thermal comfort in the home by reducing energy requirements and, compared to other existing solutions on the market (paints, cool paints), are able to reduce maintenance costs thanks to their high resistance to wear, dirt and stains.

* Centro Ceramico, Italy

** Zircon Industry Association, UK

NOTES

1

- H. Akbari et al “Advance in the development of cool materials for the built environment”, Bentham Books

2 - G.M. Revel et al “Cool products for building envelope – Part II: experimental and numerical evaluation of thermal performances” Solar Energy 105 (2014) 780-791

3 - A.Muscio et al “Sviluppo di materiali ad elevata riflessione solare per l’ottimizzazione delle prestazioni energetiche degli edifici durante la stagione estiva” Ricerca ENEA